Development and Application of Single Snorkel Refining Furnace Technology

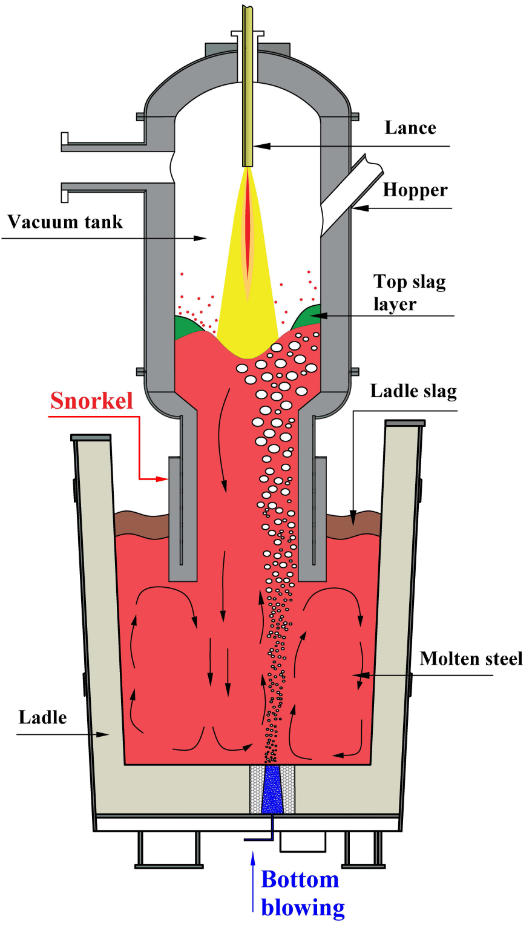

The Single Snorkel Refining Furnace (SSRF) is a secondary refining device for molten steel,which was originally invented by Prof. Jian ZHANG at the University of Science and Technology Beijing in the 1970s. The main structure of the SSRF is composed of a snorkel, a lower vacuum tank, and an upper vacuum tank. When working, a large-diameter snorkel is inserted into the ladle containing molten steel. Under vacuum conditions, the inert gas is blown into the molten steel through the porous bricks at the bottom of the ladle, then the molten steel is cyclically stirred. Various refining functions can be realized, such as vacuum degassing, decarburization, desulfurization, inclusion removal and alloying of molten steel.

A schematic illustration of the SSRF

The team of Prof. Guoguang CHENG (ZHANG’s student) has carried out extensive research on SSRF for more than 40 years, and has obtained a relatively complete theoretical system on the liquid steel flow behavior, bubble evolution behavior, impurity elements and inclusion removal mechanism during the refining process. Promoting the industrial application of SSRF is also an important goal of the technology development. Since 1984, Prof. CHENG has cooperated with many domestic iron and steel manufacturers to carry out industrial trials on the refining of special steels using SSRF, and successfully applied it to the refining of bearing steel, IF steel, and non-oriented silicon steel. Long-term industrial batch tests have proved that this furnace has the technical advantages of high refining efficiency, low production cost and simple structure in special steel refining, and is especially suitable for the production of ultra-low carbon steel and ultra-low sulfur steel.

Recently, Prof. CHENG has extend the application of SSRF to produce stainless steel and has achieved great success in the industrial test of refining 304 stainless steel. The actual performance showed that the SSRF is capable of refining stainless steel with the advantages of high decarburization efficiency, less vacuum splashing, and high chromium yield.

A snapshot of the industrial application of SSRF and the study is selected as the cover page of Steel Research International